As a leading water-cooled screw chiller manufacturer with almost 20 years of experience since 2003,MGREENBELT Chiller provides a complete range of water-cooled screw chiller from MG-WS series.

The MG series of water cooled chillers offer the most advanced design to satisfy today's industrial cooling requirements.

The entire range is assembled with components developed with well know manufacturer. The complete MG series of packaged air cooled /water cooled chillers offer max efficiency together with total reliability and are manufactured to the highest quality standard.

This new generation of water chillers is built on years of experience, the result of which is the MG series which incorporates many major advanced standard features that other suppliers charge as extra.

Feature:

1) .Cooling capacity from 7ºC to 35ºC, or if need lower outlet temperature please inform us change the offer;

2) .Stainless insulated water tank and anti-freeze thermostat can provide from us;

3) .R22/R407c/R404a/R134a refrigerant used as standard for efficient cooling.

4) .Refrigeration loop controlled by high and low pressure switches.

5) .Compressor and pump overload relays.

6) .Tube-in-shell condenser design for quick heat transfer and excellent heat radiation.

7) .Tube-in-shell evaporator for excellent cooling.

Chiller Details:

Well-known Brand Compressor

Unit adopts Germany BITZER or Taiwan HANBELL brand semi-hermetic screw compressor. The latest 5 to 6 patented screw rotor profile with excellent efficiency.

Adjustable infinite or closely stepped capacity control, features energy efficient, stable and quiet running.

Most advanced patented highest precision manufacturing process.

Built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitoring, manual reset lock-out, oil temperature sensor.

Wide range of refrigerant for option, including R134A, R407c and R22(R404A, R507c upon request).

Cooling capacity: 88kw - 800kw( 25 tons - 225 tons).

Refrigerant R22, R407C, R134A or R404a.

Screw compressors normally employed for medium to large cooling capacity, BITZER, HANBELL for options, the output power of screw compressor can be controlled automatically by control system. Furthermore, there are four phases for choosing: 25%-50%-75%-100%. And the motor of the screw compressor is star delta start to reduce the impact on power grid.

Shell and Tube type condenser is normally called water cooled type,this series chiller need to employ water cooling tower to discharge the heat, which is always used for large cooling capacity or the local place temperature is higher than 40 degree celsius.

Adopt microcomputer controller, display the temperature ,protect, fault code and etc to the control panel, easy to operate, PLC for options.

The electric components we use SCHNEIDER brand, as you know the electricity is very important for the chiller, also affect the safety of the operator, schneider is what we trust.

High efficient shell and tube type evaporator and condenser to save 30% energy.

Refrigerating system welded with oxygen free method ,to reduce oxides and ensure the smooth surface.

Easy Installation, Reliable Running

Closely stepped start-up, minimize impact to electricity.

Steady and safe running, low vibration, easy for installation.

Compact structure, less space demand and light in weight, easy for transport and installation.

Completely wired, inspected and tested pre-delivery, saving installation time and cost.

Moves the parts to process strictly ,wipes the row of gas oil counterbalance design specially, the maintence cycle is long ,the trouble-free moves above for 40000 hours.

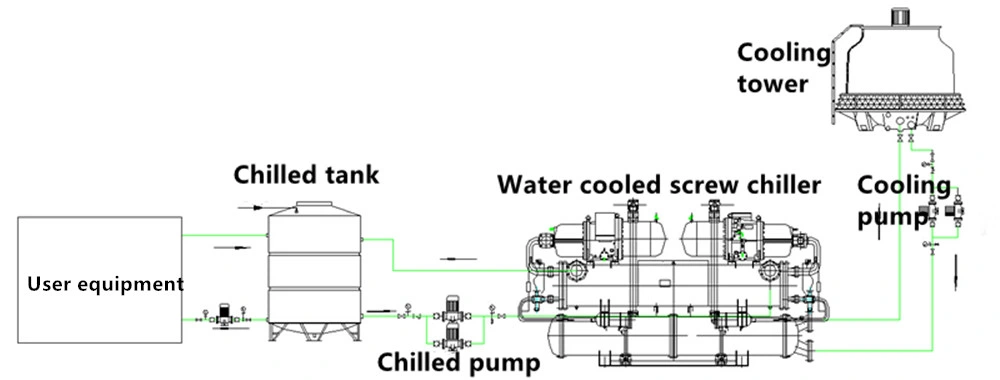

We provide complete whole system for Water Cooled Water Chiller

(1). Water Cooled Water Chiller

(2). Water Cooling Tower

(3). Stainless Steel Insulated Water Tank

(4). Water pumps

• Shell and tube evaporator and condenser, high efficient thread red copper tube (material change on request).

• Siemens PLC control, LCD touch screen interface, easy operation, Standard design charged.

• R22, CFC free R407c, R134a for option.

380V-415V-480V/50/60HZ, 3PH for standard design. Chiller unit can be supplied according to diffierent requirements.

Data Sheet

| Type | MG-30W | MG-40W | MG-50W | MG-60W | MG-70W | MG-75W | MG-85W | MG-90W | MG-100W | MG-110W | ||

| Cooling capacity | 0ºC | kw | 67.8 | 92.5 | 121.3 | 132.1 | 161.1 | 176.8 | 208.3 | 220.1 | 240.8 | 260.7 |

| -5ºC | kw | 55.7 | 76.0 | 99.7 | 108.5 | 132.3 | 145.2 | 171.1 | 180.8 | 197.8 | 214.1 | |

| -10ºC | kw | 45.4 | 61.9 | 81.2 | 88.5 | 107.8 | 118.3 | 139.4 | 147.3 | 161.2 | 174.5 | |

| Power Supply | 380-420V,50HZ or 440-480V, 60hz | |||||||||||

| Refrigerant | Type | R22/R407C/R404A/R507 | ||||||||||

| Control type | Thermostatic expansion valve | |||||||||||

| Compressor | Type | semi-closed screw type | ||||||||||

| Power(kw) | 21.4 | 28.2 | 35.4 | 38.8 | 47.2 | 51.4 | 57.9 | 60.9 | 67.0 | 68.8 | ||

| Start mode | Y-△ | |||||||||||

| Capacity | 25-50-75-100(%)or 25-100(%) | |||||||||||

Evaporator | Type | High efficiency copper tube shell and tube type | ||||||||||

| Water Flow(m³/h) | 0ºC | 11.6 | 15.9 | 20.8 | 22.6 | 27.6 | 30.3 | 35.7 | 37.7 | 41.3 | 44.7 | |

| -5ºC | 9.5 | 13.0 | 17.1 | 18.6 | 22.7 | 24.9 | 29.3 | 31.0 | 33.9 | 36.7 | ||

| -10ºC | 7.8 | 10.6 | 13.9 | 15.2 | 18.5 | 20.3 | 23.9 | 25.3 | 27.6 | 29.9 | ||

| Inlet/Outlet Dia.(mm) | DN50 | DN65 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | DN100 | ||

Condenser | Type | High efficiency threaded copper tube shell and tube type | ||||||||||

| Cooling Water Flow(m³/h) | 16.8 | 22.8 | 29.5 | 32.2 | 39.3 | 43.0 | 50.2 | 53.0 | 58.0 | 62.1 | ||

| Inlet/Outlet Dia.(mm) | DN50 | DN65 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | DN100 | ||

Dimension | L | mm | 2300 | 2300 | 2500 | 2500 | 2500 | 2800 | 3200 | 3200 | 3500 | 3500 |

| W | mm | 750 | 750 | 750 | 750 | 800 | 800 | 800 | 800 | 900 | 900 | |

| H | mm | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1800 | |

| dB Noise | 73.1 | 73.7 | 74.8 | 78.4 | 79.0 | 79.2 | 79.5 | 80.4 | 80.4 | 83.1 | ||

| Weight(KG) | 660 | 700 | 800 | 975 | 1000 | 1150 | 1250 | 1400 | 1600 | 1750 | ||

Advantages of water cooled chiller

1). Water cooled chiller with higher efficiency and energy saving, condenser cooled by cooling water from cooling tower.

2). smart design, just need small space and low noise without fans.

3). Price is cheaper than air cooled

4). Most popular for larger production process and hot place.

Application Industry

MG-WS series Water Chiller can precisely control the exactly temperature , which requested by the modernized machinery production, and greatly improved the production efficiency and product quality. MGREENBELT Industrial chiller is a good partner for the modernized industry , which feather as easy to operate with reasonable design, high quality and complete range of specifications.

Food (Beverages, Confectionery, Chocolate, Storage)

Plastics (Injection, Blow Molding, Extrusion, Film Extrusion, Thermoforming)

Paper (Manufacturer, Printing, Card Board, Labels, Plastic Film)

Chemical (Petro Chemical, Paints, Solvents, Temperature Control)

Mechanical (Welding, Cutting, Profiling, Polishing, Rolling, Grinding)

Other (Wood, Ceramics, Gold & Silver, Pharmaceutical, Textile)

Package

Juice chiller machines/ chiller for juice production line/ Beverage Water Cooled chiller

Packaging : We consider all different potential situation in the delivery, so we use every prevention measures to avoid any potential inconvenience or trouble

a.Bulk cargo: Standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the surface of our products.

b. Container cargo: the equipment will be bound firmly and won't easily swing to the side, or up, or down.

Shipping: Deliver from Qingdao, Shanghai, Guangzhou, Tianjin, Hangzhou, within 15-35 days after the payment.

Certificate

Mgreebelt chiller got CE, UL, SABER, CSA certificate to different market.

MGREENBELT COMPANY

FAQ

1. Are you manufacturer or Trade Company?

We are OEM professional factory, founded in 2003.

2. What's the order process?

.Inquiry---provide us all clear requirements.

.Quotation---quotation form with all clear specifications.

.Contract confirmation---provide correct contract details.

.Payment terms--- T/T 30% in advanced, balanced before shipment.

.Production---mass production

.Testing: 8hours, to ensure the quality of the machine

.Shipping--- by sea, train, air or courier. Detailed picture of package will be provided.

.Installation

3.What terms of payment you use?

T/T, L/C,etc.

4. How to get a prompt quotation?

When you send the inquiry to us, pls kindly send it with below technical information.

1)water chiller type: Air cooled or water cooled

2)Cooling capacity: _____ Kcal/hr or _____KW

3)Refrigerant: R22 or others

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

As a professional industrial chiller manufactuer and solution provider , we can supply kinds of chillers to meet your different cooling requirement, if the chillers above is not workable for you, please feel free send needs to us directly.

Contact Person: Libra Zhang